Benefits

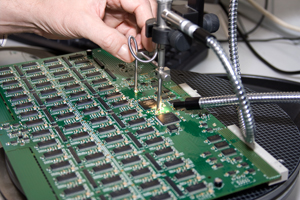

For the best in Repairs and Rework at G&B our added value benefits include:

- IPC 7711 - Rework of Electronic Assemblies - Certified operators

- IPC 7721 - Repair and Modification of Printed Board and Electronic Assemblies - Certified Operators

- Latest in RoHS and Non RoHS rework equipment

- Complaint/Return Seriousness Assessment Facilities

- Structure to notify notified bodies involved in certification of product

- Structure to notify contracted distributors

- Investigation of route cause of failure facilities

- Fault analysis data production for customer review during product upgrade.

- A fully air conditioned ESD controlled and certified rework facility

- Serial number control and traceability

- ERP Database Control

Capabilites

The capability to deliver the most effective repairs and reworks is assured by our experience and resources for the:

- Rework of BGA’s µBGA’s RoHS and non RoHS

- Rework of all SMT component packages

- Rework of conventional / leaded components

- Corrections / field safety corrective action including:-

- return to the supplier / manufacturer for modification,

- exchange

- destruction

- retrofit

- permanent or temporary changes to labels or instructions

- software upgrades

- special end user follow-ups

- if medical recall of patents for retest (for IVDs)

- calibration of maintenance changes

- Record keeping in accordance with your industry requirements.

- Serial number control

Quality

It is crucial that the quality of rework completed is to the highest possible standard and for G&B this is of the utmost importance. By ensuring that their rework operators receive the most up to date IPC training, giving them the correct calibrated tools for the job and ensuring that this is controlled by a comprehensive quality system. G&B can clearly identify the seriousness of the fault in hand and their customers can rely on them for a first class repair and rework service.

Quality standards include.

- ISO 9001:2015,

- IPC-A-610D (Inspection)

- IPC J-STD-001 (Assembly)

- IPC 7711/7721 (Rework)

- BS EN 61340-5-1/2 (ESD)

In addition to these standards we also have the following Medical quality standards:

- FDA Registered and Inspected

- ISO 13485:2016

- Certification for the accreditation of foreign manufacturings in Japan

Established as a supplier to the US, Japan and Europe, G&B Manufacturing Services are well placed in the international market for delivering global solutions, understanding primary regulatory bodies and the subsequent demands on businesses across industry standards. Please contact us for more information on 01420 474188 or email us to understand how we can help your business in these markets.

Plant List

At G&B our investment production facilities ensures that all rework and repairs are catered for competitively:

- Ersascope BGA Inspection

- Ersa BGA Rework System

- PACE De-soldering Station

It is vital to manufacturers to ensure high levels of competence with both repairs and rework either by assisting customers with their development stages, or for repairing returns, implementing upgrades or assisting test with investigations. Hence it is essential to have the accurate equipment and IPC trained and certified operators.

It is vital to manufacturers to ensure high levels of competence with both repairs and rework either by assisting customers with their development stages, or for repairing returns, implementing upgrades or assisting test with investigations. Hence it is essential to have the accurate equipment and IPC trained and certified operators.